Small Hole Manufacturing in Medical

PRECISION TOOLING MEDICAL COMPONENTS

GLE is a provider of precision tooling and medical components used across the medical industry.

Vascular tipping dies, catheter dies and suture tooling are all dies and tooling in the medical industry which require small hole manufacturing. Along with these dies and tooling, GLE-Precision also manufactures a variety of fixtures and parts and components for various customers in the medical industry all requiring small hole manufacturing. If you are a manufacturer of suture needles, we manufacture the carbide and steel dies that are used to form the needles. Coining dies, punches and pierce dies are all products we are familiar with and can manufacture with the highest of quality. We have small hole manufacturing capabilities, which allow our precision machinists to machine a hole .003″ into a part. We also have the capabilities to manufacture a .002″ OD pin. Both of these extreme capabilities are used in the manufacturing of catheter dies and suture tooling.

Small Hole Manufacturing in Carbide

Carbide tooling and fixtures provide resistance to wear applications for your specific application. Our medical components have aided medical companies to stay on the cutting edge of medical technologies. Small holes, tight tolerances and high surface finishes are all requirements from our medical customers. Small hole manufacturing is a common, frequently performed machining operation. Holding a hole size of .010″ may be common, but holding a hole size of .002″ is where it gets interesting. GLE-Precision is your one stop shop for all of the above criteria.

Gaging Applications with Small Hole Manufacturing

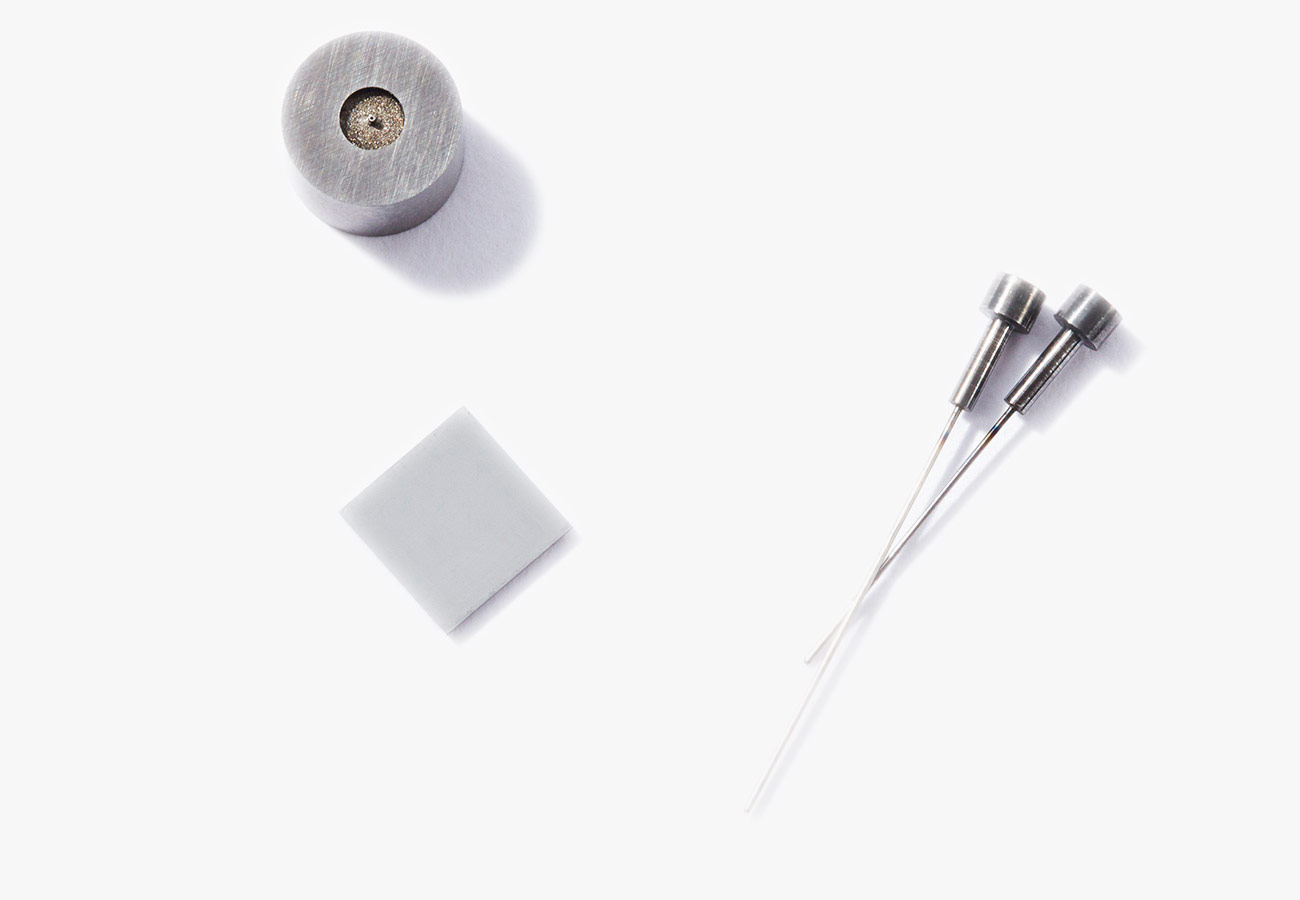

GLE-Precision also manufactures the precise pin gages that are used to check the hole size of the small needles mentioned above. The machinists at GLE-Precision are capable of manufacturing steel pin gages to .002″ (.0508mm) with a tolerance of .000020″ (.000508mm). In the image below you will see a ring gage with a .002″ (.0508mm) through hole. Hole size would be checked with a pin gage, made by GLE-Precision with gage blocks calibrated to NIST Standards. A few years ago, the GLE-Precision Sale’s Team sent out packages to current and prospect customers of a piece of steel with a .002″ (.0508mm) hole machined into. We also had to include a magnifying glass because without it, the hole was almost impossible to see.

Small Hole Manufacturing

As a global supplier, with over 50 years’ history with major manufactures, GLE manufacturers wire bonding and semiconductor parts and components used throughout the chip industry. High finishes (mirror finishes) and flatness are of prime importance for manufacturing the finished product. Hole sizes to .003. Jewel clamps, connectors, gluing and injection nozzles, punches and tooling are a few of the parts GLE has manufactured for the chip industry.

Wire bonding involves creating interconnections between an integrated circuit or other semiconductor device and its packaging during fabrication