Welcome to GLE. Our capabilities consist of:

Small parts(ID/OD/OAL: .002” [.0508mm] or less), lapping (.4RA [.01016 micron] or less) and precision tolerances (.000003” [.000076mm] or less).

A Global Precision Machining Leader

(Micro Precision Machining Experts)

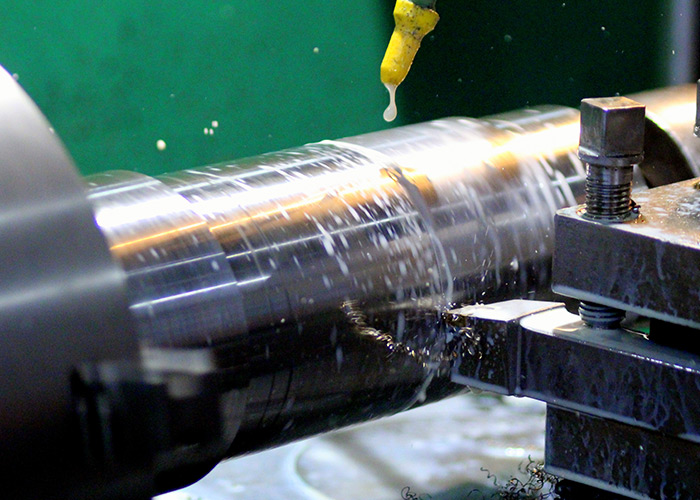

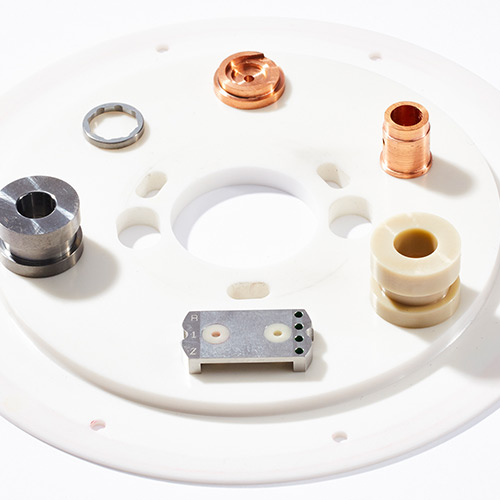

GLE-Precision is a cutting-edge global precision machining leader. Our precision machinists grind tungsten carbide, ceramic and other hard exotic materials to customer specifications. Primarily, we produce make-to-print precision machined parts. Additionally, these parts are manufactured to customer specifications in our precision machine shop. Critically, the tight tolerances, small parts and high surface finishes can not be accomplished by other precision machinists with the accuracy that our precision machining services can provide.

To explain more about our make-to-print abilities, the following link takes you to our capabilities page: https://www.gle-precision.com/tight-tolerances/. Even more, browse through our website to read about the diverse products and market segments we work with. Foundationally, GLE is a large contributor to the fiber optic, semiconductor, aerospace, waterjet, battery, and medical industries. Of course, GLE-Precision is always looking to be involved in the next big precision machining project.

Precision Machining Make-to-Print Parts

The make-to-print parts we manufacture for our customers include various tooling, dies and components. Likewise, our precision machining techniques are used to grind hardened steels, carbides and ceramics to meet customer requirements. Also, depending on the tolerances and precision machining services required to produce your part, an Engineer Contract Review may occur. Of course, our customers are involved every step of the way. Granted, we value transparency and are committed to continuously improve ours here at GLE.

Furthermore, our experienced precision machinists are able to meet any and all of your precision requirements. For example, our capabilities include precision machining small holes (.002″ [.0508mm]), lapping surfaces to .4RA (.01016 micron) and holding tolerances to .000003″ (.000076mm). Also, if customer parts require a coating, we work with the best coating companies to ensure your requirements are met. For this purpose, some of the jobs include but aren’t limited to black oxide, chroming, TiN coating and various heat treatments.

Quality with Precision Machining

GLE-Precision is AS9100 Certified, ISO 9001:2015 certified and ITAR Registered precision machine shop. Additionally, we have a temperature controlled precision machining gage lab on site that adheres to NIST Standards. The gage blocks used to manufacture precision gages are calibrated to NIST standards. Although GLE is not currently an ISO 17025 certified precision machine shop, we work with some of the top calibration labs accredited to ISO 17025 standards.

Naturally, GLE has an expedited gaging program. Therefore, lead time concerns are eliminated for our customers. In fact, if the material is in-house, we can typically expedite the delivery in 1-3 weeks. Additionally, we are working to get material quickly from our parent company; Hyperion to offer additional expedite services. Certainly read more about Hyperion in the following link: Hyperion Materials & Technologies acquires GLE Precision (hyperionmt.com) In fact, customers are encouraged to contact our sales engineers to discuss gaging requirements. As a result of top tier-customer service and communication, GLE meets all precision machining service and quality needs every time.

Testimonials

I have conducted business with GLE for over 10 years. The quality and engineering is excellent. The inside staff always quotes in a reasonable time frame, which is very important.

GLE is a partner, not just a supplier. That is what we need.

We are very pleased with GLE’s weekly updates of our orders. This is very refreshing to see and know that your team is dedicated to ensuring our needs are GLE’s priority. Thank you!

They work together and put you in contact with the person who can solve the problem. I have had many years of great service.

Overall a great company to work with!

It has been a pleasure having GLE as a valued supplier of quality products for over 17 years.

I appreciate the consistently excellent quality of the products that I order from GLE.

GLE has the best prices and that’s why they have all our business.

I could not be any happier. Thank you for the outstanding product!

Excellent Customer Service and communication!