Materials: Working with Ceramic

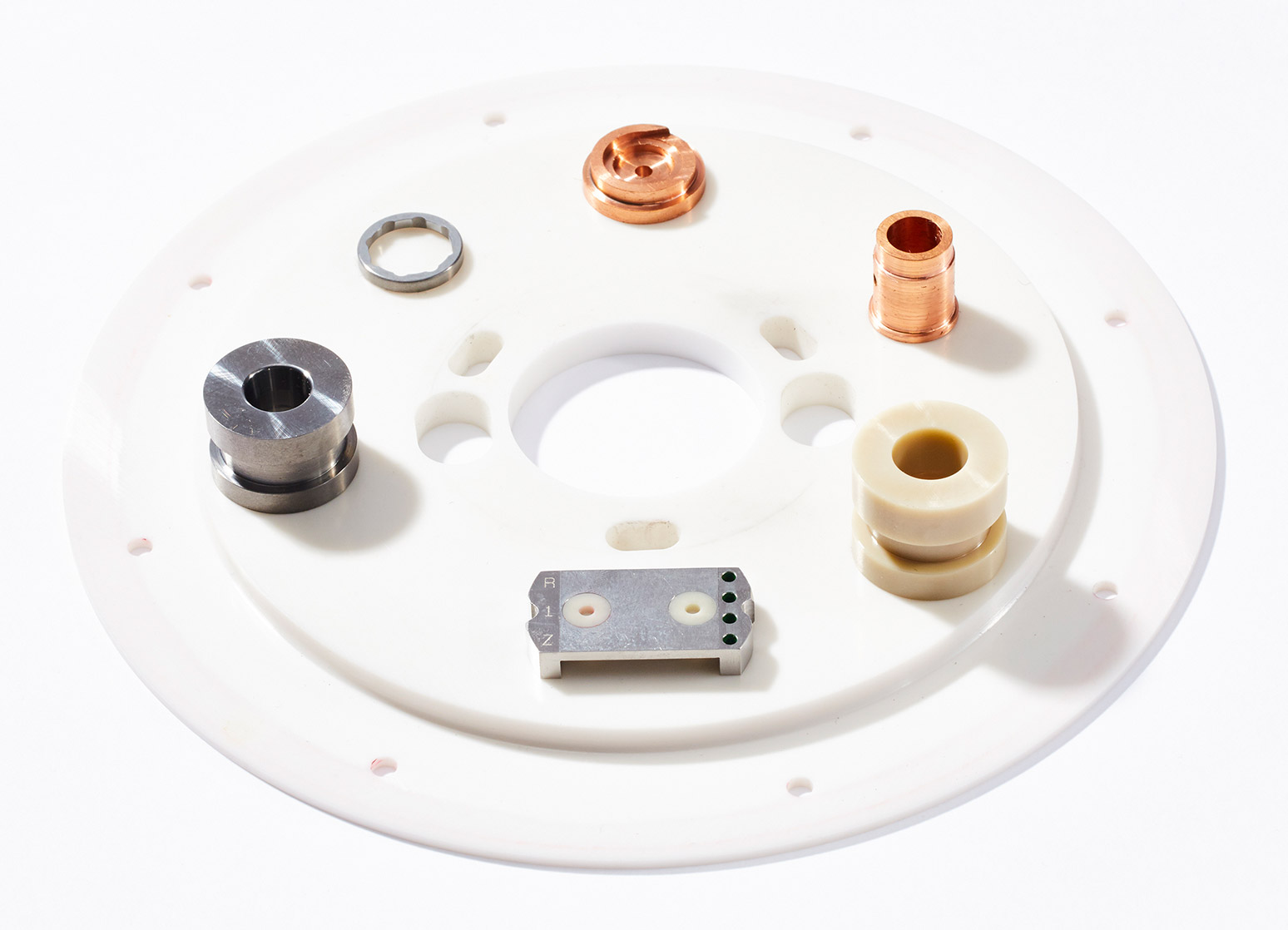

GLE-Precision is a global leader in working with ceramics. Other materials we grind include tungsten carbide machining and other hard exotic materials machined to customer specifications. We produce standard carbide gages/gauges, tungsten carbide tooling, ceramic tooling products and a combination of carbide and ceramic along with other hard materials. The products are used in a broad range of applications.

Working with Ceramic Components

GLE-Precision works with many exotic and standard materials to produce precision products for our customers, including carbide, ceramic and steel. Different grades of ceramics are used when manufacturing make-to-print parts for our customers. Zirconia ceramics and Alumina ceramics are a few of the most common grades we work with.

Background of working with Ceramics

Ceramic components are extracted from the earth through mining. The materials are milled to very fine powders and sintered. The sintering process transforms the ceramic into extremely hard, corrosion-resistant materials. Sintering is a high-temperature heating process that encourages tiny grains of powdered material to fuse together. In extremely corrosive environments, ceramic is used to replace metal, plastic, polymers or fabrics. Ceramic materials are valued for their strength, hardness and resistance to abrasion and corrosion. Alumina Oxide is the most common material used for structural ceramic parts. It is used in applications from medical to aerospace, from bearings to instrumentation equipment. Alumina demonstrates excellent resistance to organic solvents and alkaline solutions up to 122 degrees Fahrenheit. The Vickers Hardness (HV) for these materials is in the 2000 range. Zirconia Oxide, while more expensive than Alumina Oxide, is also a very popular material. Zirconia Oxide has a very high level of mechanical strength along with high resistance to crack propagation, chemicals (acids and bases), impact, wear, corrosion and erosion. The Vickers Hardness (HV) for these materials ranges from 1290 to 1600.

At GLE-Precision we utilize structural ceramic to produce gages, plungers and bushings. Other specific parts are machined to customer prints for industries such as battery, waterjet and flow metering.

Please contact us and we can recommend the best material to use for your application. We can be reached at 989-652-6136 or visit our website at www.gle-precision.com.