GLE Powers the Battery Industry

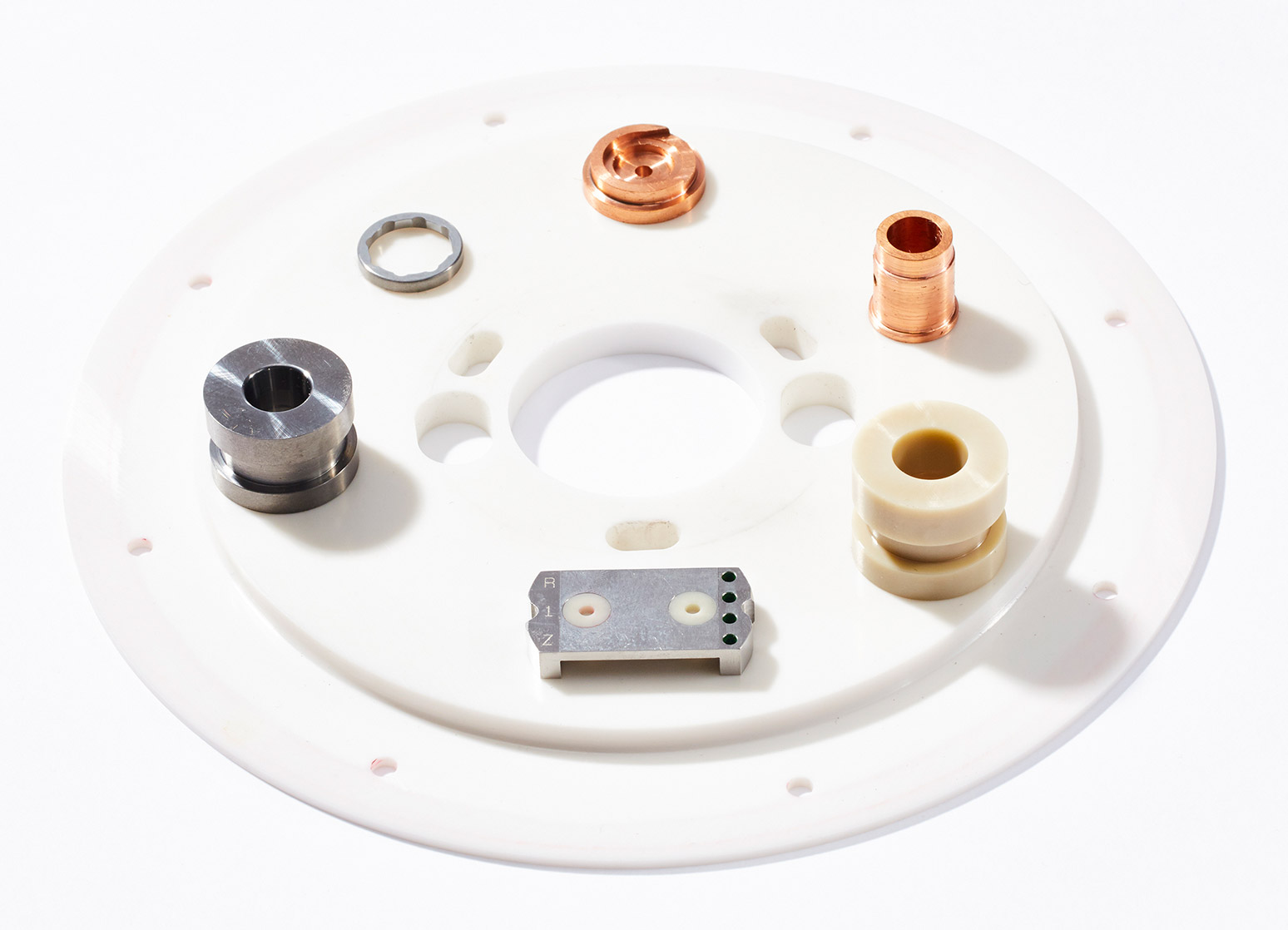

If you asked the largest battery manufacturers in the world, they would tell you that GLE powers the battery industry. For decades, we have been an essential supplier of the names you see on batteries every day. Our ability to work with unique materials, as well as our machining capabilities, sets us apart from other manufacturers.

Battery Manufacturing

As electric technologies become more advanced, the need for batteries to power them has increased exponentially. Manufacturers have adapted very well, developing new technologies to increase battery power and life. GLE has stood by their side, helping R&D teams by developing prototypes and manufacturing teams through tooling and dies.

To achieve the required precision in battery manufacturing, tooling must be extremely accurate. Due to the global demand for portable power, manufacturers must produce batteries in high quantities. This can produce wear on tooling, which can be mitigated through precision tolerances and high surface finishes. Through tight tolerances, manufacturers also reduce scrap and the cost of quality.

Ceramic has proven itself as a crucial material to battery manufacturing. This is because of its wear properties, hardness, and most importantly non-conductive nature. GLE has decades of experience with custom ceramic parts, and have helped some of the top battery manufacturers develop new tech with it. We are looking forward to seeing how the next decade of new technology revolutionizes the battery industry.