Computer Chip Manufacturing

Semiconductor Chip Manufacturing

Due to the COVID-19 pandemic, supply chains around the world have suffered shortages. As restrictions lift in some places, consumers are beginning to demand products again. However, manufacturing facilities that are under restrictions still are struggling to meet that demand. One industry that has seen extreme supply chain shortages is semiconductor/computer chip manufacturing. As a manufacturer in this industry, GLE has seen a dramatic increase in order quantity because other suppliers are not able to meet demands.

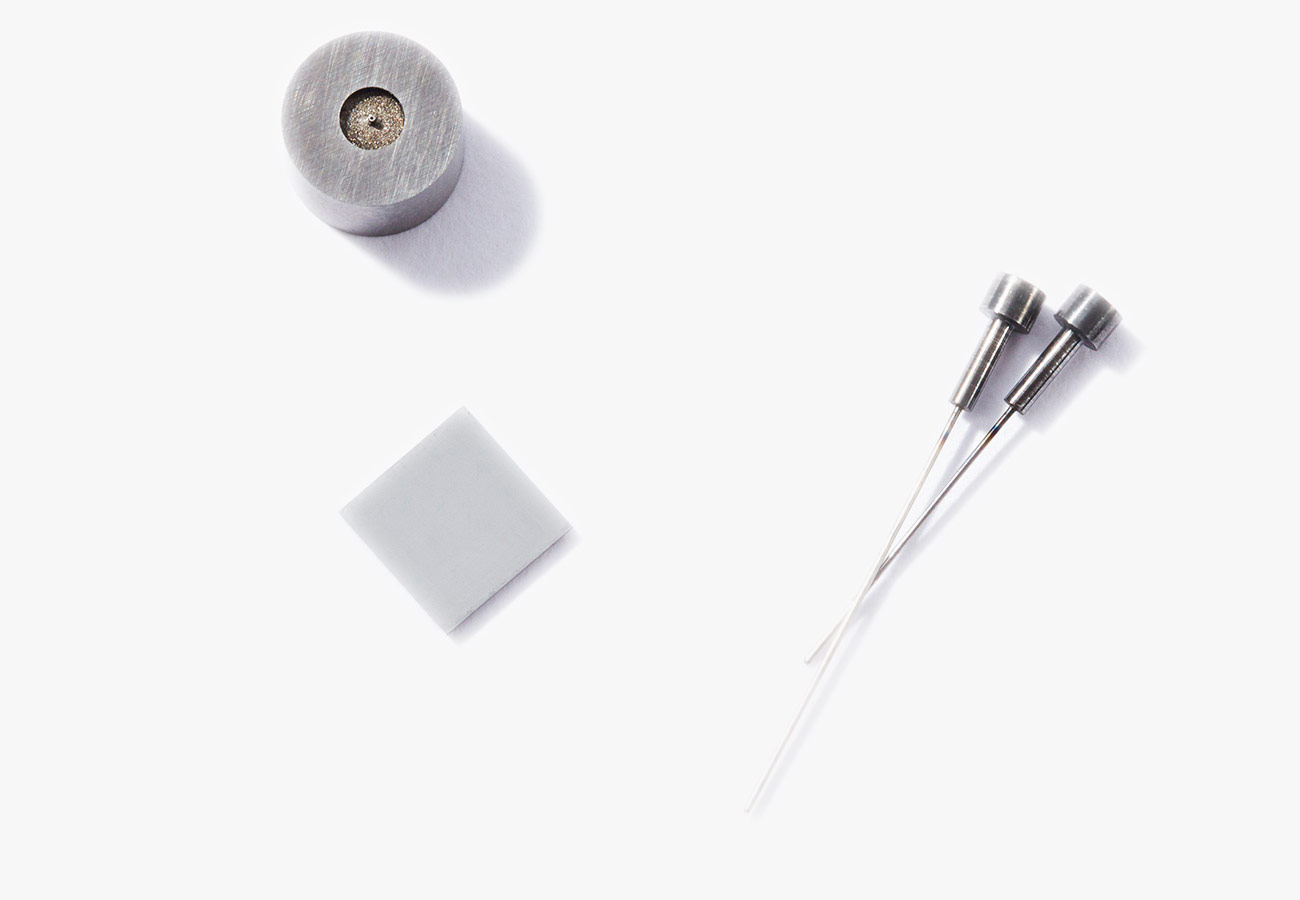

The parts that we make range from precision dies and punches to consumable parts for tier 1 suppliers. These parts are most often made of carbide because of its increased wear capabilities, hardness, and ability to hold better finishes compared to hardened steel. Ultra-precision tolerances and mirror-like (or better) surface finishes are critical in chip manufacturing. These features allow tooling to produce better parts and last longer. There are multiple companies that can hold these tolerances and finishes, but not many can apply them to custom parts smaller than a fingernail.

Computer Chip Applications

Technology has been advancing exponentially for the last few decades. From CNC mills, lathes, and grinders to artificial technology, computers are at the heart of this development. Advances in chip technologies have allowed computers to get smaller and faster. It’s been over a decade since they first became small enough to be integrated into cell phones. Smartphone manufacturers now unveil their lineup of next-generation phones with new chips every year. It seems like every year there are advances in these cell phones that make the previous year’s technology obsolete, or at least outdated.

Outside of consumer applications, the market for chip technology is growing. More businesses are trusting technology to make decisions every day. In 2018, 50%-60% of stock market trades (and up to 90% in volatile markets) were made by computers. Some people are even finding success in developing AI to beat the stock market. Manufacturing has always been one of the driving forces behind AI because better productivity and quality correlate directly to dollars saved. GM partnered with Autodesk to create AI design software that resulted in a prototype that was 20% stronger, while being 40% lighter, than the original design. These incredible strides show how technology is invading, and even taking over, many aspects of global commerce.

Manufacturing Challenges

As the demand for computer chip manufacturing grows, facilities must ensure that quality standards are being met while increasing production quantity. The tight tolerances and high surface finishes required make this an especially complex challenge. Manufacturing technology has not yet progressed to the point where the tooling and production parts in chip technology can be run entirely by machines. Operators must still run production lines and inspect parts to ensure the stringent quality requirements are met. Deviations in quality could result in catastrophic failures, especially since more and more essential systems rely on computers.

GLE Precision has seen a large demand increase for computer chip manufacturing tooling and production parts. We have a reputation for producing parts that not many other companies can, and having top-notch quality. We can hold tolerances to .000003″ (.0762µm), and we can produce surface finishes of 0.4 µin (.01016 µm) or better. This makes us the perfect partner for industry leaders in the semiconductor/chip, aerospace, medical, fiber optic, waterjet, battery, oil, and other markets. Contact us today to see how we can help you push the limits of technology forward!